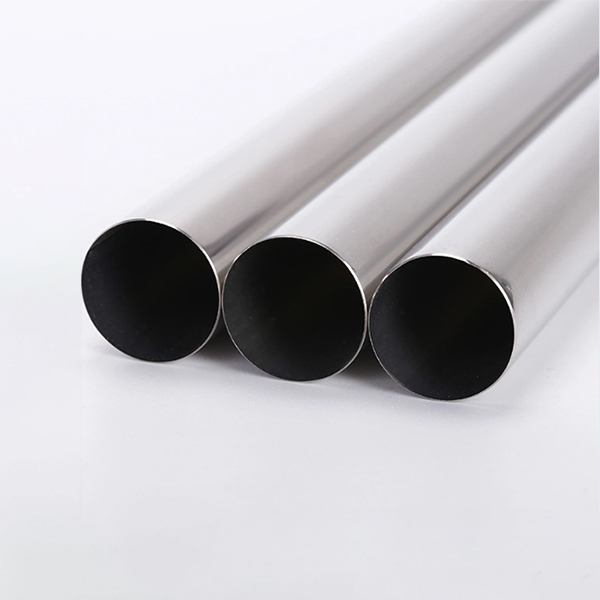

TA2 titanium alloy tube yo gukoresha inganda

TA2 Umuyoboro wa Titanium, Ibyiza

TA2 Umuyoboro wa Titanium loy Ugereranije nibindi bikoresho byuma, bifite ibyiza bikurikira:

1. Imbaraga zidasanzwe (imbaraga zingana / ubucucike) (reba ishusho), imbaraga zingana zirashobora kugera kuri 100 ~ 140kgf / mm2, mugihe ubucucike ari 60% gusa byibyuma.

2. Ubushyuhe bwo hagati buringaniye nibyiza, gukoresha ubushyuhe burenze dogere ijana kurenza aluminiyumu, mubushyuhe bwo hagati burashobora gukomeza imbaraga zisabwa, burashobora gukora mubushyuhe bwa 450 ~ 500 ℃ igihe kirekire.

3. Kurwanya ruswa neza, titanium hejuru yikirere yahise ikora urwego rwa firime imwe kandi yuzuye ya oxyde, ifite ubushobozi bwo kurwanya isuri itandukanye yibitangazamakuru.Titanium muri rusange ifite imbaraga zo kurwanya ruswa mu itangazamakuru rya okiside kandi ridafite aho ribogamiye, cyane cyane mu mazi yo mu nyanja, chlorine itose hamwe na chloride.Ariko mukugabanya imiti, nka hydrochloric acide acide, titanium ruswa irwanya ubukene.

4. Titanium ivanze hamwe nubushyuhe buke bwo hasi hamwe nibintu bito cyane, nka TA7, birashobora gukomeza plastike kuri -253 ℃.

5. Modulus nkeya ya elastike, itwara ubushyuhe buke, nta ferromagnetism.

6. Gukomera cyane.

7. Kashe mbi yumutungo hamwe nubushuhe bwiza.

Kuvura ubushyuhe Titanium alloy irashobora kubona ibyiciro bitandukanye hamwe na microstructure muguhindura uburyo bwo gutunganya ubushyuhe.Mubisanzwe bifatwa ko microstructure nziza iringaniye ifite plastike nziza, ituze ryumuriro nimbaraga zumunaniro.Imiterere ya acicular ifite imbaraga ndende zirambye, imbaraga zo kunyerera no gukomera kuvunika.Kuringaniza hamwe na acicular ivanze ifite imiterere myiza yuzuye.

TA2 Titanium Alloy Pipe, Uburyo bukoreshwa muburyo bwo kuvura ubushyuhe ni annealing, igisubizo no kuvura gusaza.Annealing nugukuraho imihangayiko yimbere, kunoza plastike hamwe na microstructure stabilite, kugirango ubone imitungo yuzuye yuzuye.Mubisanzwe, ubushyuhe bwa annealing bwa α alloy na (α + β) ibishishwa ni 120 ~ 200 ℃ munsi yinzibacyuho ya (α + β) - → β icyiciro.Umuti hamwe no gusaza ni ukubona icyiciro α 'nicyiciro cya metastable β icyiciro cya martensite ukonje vuba mukarere k’ubushyuhe bwo hejuru, hanyuma ukangirika ibyo byiciro byoroshye ufata mukarere k’ubushyuhe bwo hagati, hanyuma ukabona ibice byiza bya kabiri bitatanye. , nka α icyiciro cyangwa ibice, kugirango ugere ku ntego yo gushimangira amavuta.Mubisanzwe (alpha + beta) kuzimya ibishishwa muri alfa + beta) - -> inzibacyuho yicyiciro cya beta munsi ya 40 ~ 100 ℃, metastable beta alloy kuzimya muri alpha + beta) - -> icyiciro cyinzibacyuho ya beta hejuru ya 40 ~ 80 ℃.Ubushyuhe bwo gusaza muri rusange ni 450 ~ 550 ℃.Byongeye kandi, kugirango huzuzwe ibisabwa byihariye byakazi, inganda nazo zikoresha inshuro ebyiri, isothermal annealing, treatment kuvura ubushyuhe, kuvura ubushyuhe bwa deformasiyo nubundi buryo bwo gutunganya ubushyuhe bwicyuma.

TA2 Umuyoboro wa Titanium, Urwego

Umuyoboro wa Titanium, umuyoboro wo gusudira wa titanium, titanium utera tee, inkokora ya titanium, impeta yo gusudira, titanium, kugabanya titanium, titanium, inkokora ya titanium, nibindi.

TA2 Umuyoboro wa Titanium, Ihame ry'akazi rya

TA2 Umuyoboro wa Titanium, ahanini uhuza ubwoko bwose bwibikoresho bya titanium, bikoreshwa mugukwirakwiza ibintu hagati yibikoresho byose, umuyoboro ufite kurwanya ruswa yibikoresho bya titanium ubwayo, kugirango usimbuze umuyoboro rusange wumuyoboro usanzwe ntushobora guhaza icyifuzo. .Mubisanzwe ф 108 hejuru ni imiyoboro isudira.

Ibipimo byingenzi bya tekiniki

| DN (mm) | Gupima diameter yo hanze (mm) | Ibikoresho |

| 15 | 18 | TA2 |

| 20 | 25 | TA2 |

| 25 | 32 | TA2 |

| 32 | 38 | TA2 |

| 40 | 45 | TA2 |

| 50 | 57 | TA2 |

| 65 | 76 | TA2 |

| 80 | 89 | TA2 |

| 100 | 108 | TA2 |

| 125 | 133 | TA2 |

| 150 | 159 | TA2 |

| 200 | 219 | TA2 |

| 250 | 273 | TA2 |

| 300 | 325 | TA2 |

| 350 | 377 | TA2 |

| 400 | 426 | TA2 |

| 450 | 480 | TA2 |

| 500 | 530 | TA2 |

| 600 | 630 | TA2 |

Kwerekana ibicuruzwa