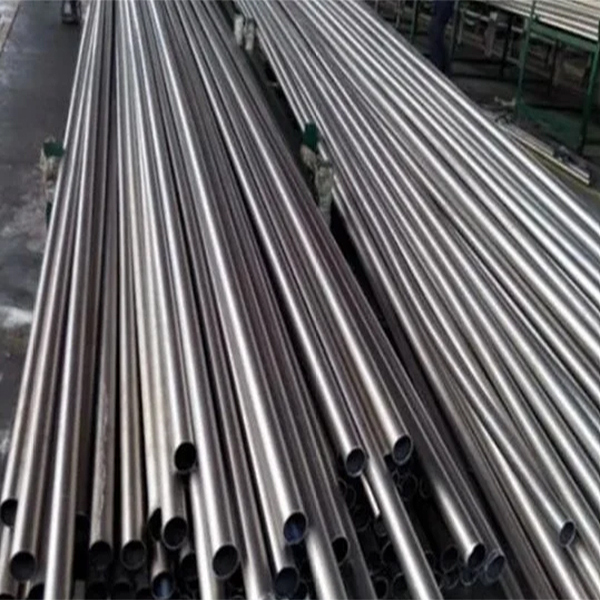

Titanium alloy TA1 tube irashobora gukoreshwa i

Titanium Alloy TA1 Tube is Ikozwe muri titanium, ishobora kugabanywamo ubwoko butatu ukurikije imiterere.. gusudira muburyo butandukanye, gusudira imbaraga hamwe bishobora kugera kuri 90% byimbaraga zicyuma cya matrix, hamwe na mashini nziza.Umuyoboro wa Titanium ufite ruswa irwanya chloride, sulfide na ammonia.Kurwanya ruswa ya titanium mumazi yinyanja irarenze iy'umuti wa aluminiyumu, ibyuma bidafite ingese na nikel base.Titanium kandi ifite imbaraga zo kurwanya amazi.

Titanium Alloy TA1 Tube, Ibipimo bifatika

GB / T 3620.1-2016 Titanium na titanium alloy amanota hamwe nibigize imiti

GB / T 3624-2010 Titanium na titanium alloy tube isanzwe

Titanium na titanium alloy tubes yo guhanahana ubushyuhe hamwe na kondenseri

TA1, TA2 na TA3 ni titanium yinganda nziza, ifite imiterere yubukanishi buhanitse, ibikoresho byiza byo guteramo kashe, kandi irashobora gusudwa muburyo butandukanye.Imbaraga zisudira zishobora kugera kuri 90% byimbaraga zicyuma cya matrix, kandi imikorere yo gukata ni nziza.Umuyoboro wa Titanium ufite ruswa irwanya chloride, sulfide na ammonia.Kurwanya ruswa ya titanium mumazi yinyanja irarenze iy'umuti wa aluminiyumu, ibyuma bidafite ingese na nikel base.Titanium kandi ifite imbaraga zo kurwanya amazi.

Ikoreshwa mugukora imiyoboro ya kondenseri mumazi yanduye, amazi arimo ibintu byinshi byahagaritswe, kandi kumuvuduko mwinshi.

Titanium Alloy TA1 Tube, Ibyiciro

Ukurikije amateka

1. aluminium na tin ibintu byongewe kuri titanium.

2. ibintu bivanze nka aluminium, chromium, molybdenum na vanadium byongewe kuri titanium.

3. aluminium na vanadium byongewe kuri titanium.

Umuti wa Titanium ufite imbaraga nyinshi nubucucike buke, imiterere myiza yubukanishi, gukomera no kurwanya ruswa.Mubyongeyeho: titanium alloy process imikorere irakennye, gukata bigoye.Mugutunganya bishyushye, biroroshye cyane gukuramo umwanda nka hydrogen, ogisijeni, azote na karubone.Hariho imyambarire idahwitse, inzira igoye.

Igabanijwe nibintu bivanze

Umuti ushingiye kuri titanium hamwe nibindi bintu byongeweho.Umusaruro w’inganda wa titanium watangiye mu 1948. Ibikenewe mu iterambere ry’inganda z’indege bituma inganda za titanium zitera imbere ku kigereranyo cy’ubwiyongere bwa buri mwaka kingana na 8%.Umusaruro wumwaka wibikoresho byo gutunganya titanium bigeze kuri toni zirenga 40.000, hafi 30 yubwoko bwa titanium.Amavuta ya titanium akoreshwa cyane ni Ti-6Al-4V (TC4), Ti-5Al-2.5Sn (TA7) na titanium yinganda (TA1, TA2 na TA3).

Ukurikije ibikorwa byingirakamaro

Umuti wa Titanium urashobora kugabanywamo ibishishwa birwanya ubushyuhe, imbaraga nyinshi zivanze, imiti irwanya ruswa (ti-molybdenum, ti-Palladium alloy, nibindi), ubushyuhe buke hamwe nibikorwa bidasanzwe (ububiko bwa ti-fer hydrogène hamwe nibikoresho bya ti-nikel alloy), nibindi. Ibigize nibiranga ibisanzwe bisanzwe byerekanwe kumeza.

Titanium Alloy TA1 Tube, Koresha

Titanium Alloy TA1 Tube used Ahanini ikoreshwa mugukora moteri yindege ya compressor yindege, ikurikirwa na roketi, misile nibice byindege byihuse.Mu myaka ya za 60 rwagati, titanium hamwe n’ibisigazwa byayo byari byarakoreshejwe mu nganda rusange mu gukora electrode mu nganda za electrolysis, kondereseri y’amashanyarazi, ubushyuhe bwo gutunganya peteroli no kuvoma amazi yo mu nyanja, hamwe n’ibikoresho byo kurwanya umwanda.Titanium n'ibiyikoze byahindutse ubwoko bwibikoresho byubaka ruswa.Mubyongeyeho, ikoreshwa kandi mugukora ibikoresho byo kubika hydrogène no gushushanya ububiko bwo kwibuka.

Ubushinwa bwatangiye kwiga kuri titanium na titanium mu 1956. Hagati mu myaka ya za 1960, ibikoresho bya titanium byakozwe mu nganda maze biteza imbere bivangwa na TB2.

Ibigize imiti

| Icyiciro | N | C | H | Fe | THE | Al | IN | Nibyiza | Mo | In | Of | Imbaraga za Tensile (MPa) | Imbaraga Zitanga (MPa) | Kurambura (%) |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal | 240 | 138 | makumyabiri na bane |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal | 345 | 275 | 20 |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal | 450 | 380 | 18 |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | 550 | 483 | 15 | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal | 895 | 828 | 10 |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal | 345 | 275 | 20 |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal | 620 | 70 | 15 |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 02-0.4 | 0.6-0.9 | Bal | 438 | 345 | 18 |

| Andika | Turashobora kandi gutanga TB3, TB6, TC4, TC6, TC11, TC17, TC18 dukurikije ibyo usabwa. | |||||||||||||

| Bisanzwe | ASTM B348, ASTM F67, ASTM F136, ISO5832-2, ISO5832-3, AMS 4928, AMS 4930, ASTM F1295, ASTM F1713, MIL-T-9047 | |||||||||||||

| Gusaba | Metallurgie, electronics, ubuvuzi, imiti, peteroli, imiti, ikirere, nibindi | |||||||||||||

Kwerekana ibicuruzwa